Electric Bus Battery Cell Thermal Runaway Control System

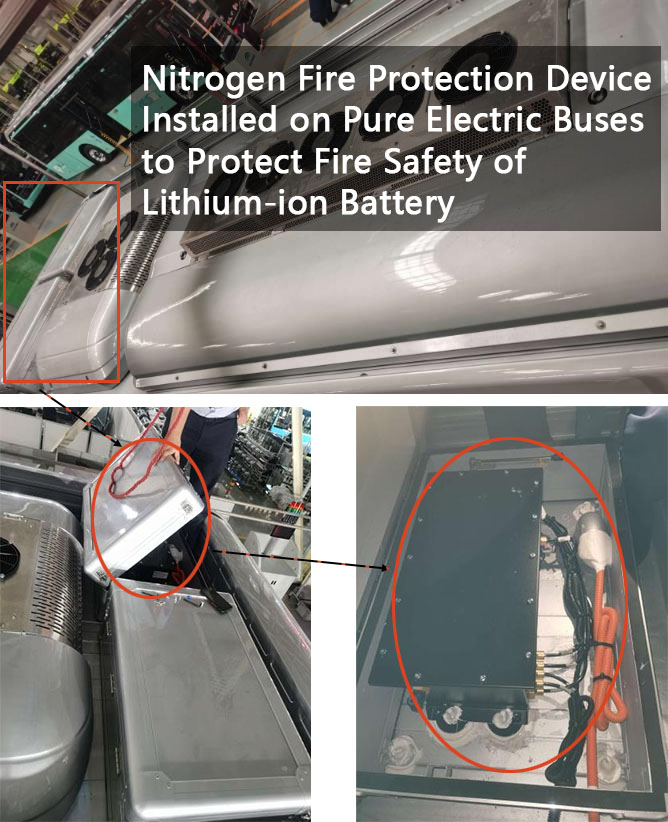

The thermal runaway causes damage to the battery cells and can lead to fire if not controlled properly. In order to address this issue, Guchen Electronic has developed an efficient thermal runaway control system for pure electric buses and other electric commercial vehicles. This solution uses a nitrogen fire protection device that uses nitrogen gas to prevent each battery cell fires from spreading to other battery cells or modules.

Battery thermal runaway is a bottleneck restricting the large-scale development of electric vehicles and renewable energy storage systems. The root cause of battery thermal runaway is a series of complex and interrelated "chain reactions" inside the battery. From local short circuit to large area short circuit, the internal temperature of the battery increases rapidly, which can reach over 800℃, causing the battery to catch fire and explode.

Therefore, it is urgent to deeply understand the evolution mechanism of thermal runaway in lithium-ion batteries and propose early warning strategies to prevent explosion accidents. Tracing the internal causes of battery thermal runaway, clarifying the coupling relationship between step-by-step reactions, revealing the dominant mechanism and dynamics of thermal runaway, and moving forward the thermal runaway warning time window are the core of fundamentally solving electric bus safety issues.

To address this issue, Guchen Team developed a highly reliable nitrogen protection technology, successfully designed a high-precision dynamic monitoring sensing module and a real-time online monitoring module for nitrogen density. Through the simultaneous and accurate measurement of the nitrogen pressure inside the battery pack, lowering the oxygen levels, the battery is controlled in an anaerobic environment so that it does not catch fire. When the battery box catches fire due to external factors, the high concentration of nitrogen can quickly cut off the thermal runaway chain reaction, thereby avoiding fire and explosion, and ensuring that the battery operates in a safe range.

The advantage of using Guchen battery cell nitrogen fire protection systems is that it can stop fires from spreading even after they have started due to ignition sources. The systems have been available commercially since 2022. It includes the following advanced technologies:

◆ Adopt nitrogen separation technology used in aviation fuel tanks

◆ 98% nitrogen concentration reaches, the detection accuracy reaches 1‰

It has the functions of real-time automatic detection and diagnosis of battery safety and nitrogen dynamic early warning, real-time anaerobic, high precision, high reliability, and full-time nitrogen protection. Regarding to the battery cell thermal runaway, it can realize pre-emptive control, achieving both a temporary and permanent solution.

◆ Real-time monitoring and dynamic early warning of battery air tightness

◆ Anti-condensation technology

It eliminates safety risks caused by condensation in electrical boxes in hot and humid areas such as coastal areas.

◆ Fully-customized solutions available

A key feature of the system is its ability to interact with other systems on the bus, such as the BMS.

1) If the BMS detects the abnormal situation such as battery cell temperature exceeds its upper limit, then this event is communicated to the nitrogen protection system so that it can take appropriate action.

2) The thermal runaway control system is an intelligent device that 24/7 monitors nitrogen pressure value and communicates critical information back to the battery management system (BMS). This allows for real-time monitoring of cell temperatures and enables preventive maintenance by identifying cells that are experiencing abnormal temperature changes or are at risk of overheating.

3) When activated by the vehicle electronics via an internal signal, the system rapidly discharges compressed nitrogen from a storage tank into the battery enclosure. The nitrogen displaces oxygen that would otherwise enable combustion reactions, preventing fire propagation and limiting the temperature rise within the enclosure. By displacing oxygen within the enclosure faster than it can be replenished from outside air, this approach minimizes risks associated with potential external sources of oxygen such as hydrogen or moisture being introduced into the enclosure through connector fittings or other openings.

This battery nitrogen protection system can keep the nitrogen concentration above 98%. It can monitor the nitrogen concentration in real time and replenish it in time, fundamentally avoiding the risk of combustion and explosion of power batteries used in electric buses. The thermal runaway risk prevention methods are now being commercialized.

Thermal Runaway in Electric Bus Battery

Due to poor thermal stability in high temperature environments, lithium-ion batteries are prone to thermal runaway after charging or discharging at high temperatures, which leads to complete combustion of the electrolyte solution inside the battery and then causes an explosion. This phenomenon is called "thermal runaway".Battery thermal runaway is a bottleneck restricting the large-scale development of electric vehicles and renewable energy storage systems. The root cause of battery thermal runaway is a series of complex and interrelated "chain reactions" inside the battery. From local short circuit to large area short circuit, the internal temperature of the battery increases rapidly, which can reach over 800℃, causing the battery to catch fire and explode.

Therefore, it is urgent to deeply understand the evolution mechanism of thermal runaway in lithium-ion batteries and propose early warning strategies to prevent explosion accidents. Tracing the internal causes of battery thermal runaway, clarifying the coupling relationship between step-by-step reactions, revealing the dominant mechanism and dynamics of thermal runaway, and moving forward the thermal runaway warning time window are the core of fundamentally solving electric bus safety issues.

Nitrogen Protection System Designed to Manage Thermal Propagation in Electric Bus Battery

Due to the battery's sealed structure and complex internal reaction mechanism, the accuracy and real-time performance of the battery's internal core status detection cannot be guaranteed. Currently, most power battery safety strategies on the market are passive fire extinguishing systems, which are difficult to extinguish and cause high economic losses. How to solve the thermal runaway problem of power batteries scientifically, timely and accurately has become an international scientific problem.To address this issue, Guchen Team developed a highly reliable nitrogen protection technology, successfully designed a high-precision dynamic monitoring sensing module and a real-time online monitoring module for nitrogen density. Through the simultaneous and accurate measurement of the nitrogen pressure inside the battery pack, lowering the oxygen levels, the battery is controlled in an anaerobic environment so that it does not catch fire. When the battery box catches fire due to external factors, the high concentration of nitrogen can quickly cut off the thermal runaway chain reaction, thereby avoiding fire and explosion, and ensuring that the battery operates in a safe range.

The advantage of using Guchen battery cell nitrogen fire protection systems is that it can stop fires from spreading even after they have started due to ignition sources. The systems have been available commercially since 2022. It includes the following advanced technologies:

◆ Adopt nitrogen separation technology used in aviation fuel tanks

◆ 98% nitrogen concentration reaches, the detection accuracy reaches 1‰

It has the functions of real-time automatic detection and diagnosis of battery safety and nitrogen dynamic early warning, real-time anaerobic, high precision, high reliability, and full-time nitrogen protection. Regarding to the battery cell thermal runaway, it can realize pre-emptive control, achieving both a temporary and permanent solution.

◆ Real-time monitoring and dynamic early warning of battery air tightness

◆ Anti-condensation technology

It eliminates safety risks caused by condensation in electrical boxes in hot and humid areas such as coastal areas.

◆ Fully-customized solutions available

Data Interaction with BMS

The system provides a layer of protection against thermal runaway events in lithium-ion batteries installed in electric buses or heavy trucks.A key feature of the system is its ability to interact with other systems on the bus, such as the BMS.

1) If the BMS detects the abnormal situation such as battery cell temperature exceeds its upper limit, then this event is communicated to the nitrogen protection system so that it can take appropriate action.

2) The thermal runaway control system is an intelligent device that 24/7 monitors nitrogen pressure value and communicates critical information back to the battery management system (BMS). This allows for real-time monitoring of cell temperatures and enables preventive maintenance by identifying cells that are experiencing abnormal temperature changes or are at risk of overheating.

3) When activated by the vehicle electronics via an internal signal, the system rapidly discharges compressed nitrogen from a storage tank into the battery enclosure. The nitrogen displaces oxygen that would otherwise enable combustion reactions, preventing fire propagation and limiting the temperature rise within the enclosure. By displacing oxygen within the enclosure faster than it can be replenished from outside air, this approach minimizes risks associated with potential external sources of oxygen such as hydrogen or moisture being introduced into the enclosure through connector fittings or other openings.

Mass Production of Battery Cell Thermal Runaway Control System

The system involves using nitrogen as protective gas. Nitrogen gas is injected into the enclosed battery packs. This method works by keeping oxygen away from burning materials (electrolyte etc.) so they cannot continue burning once they are no longer exposed to heat or flames.This battery nitrogen protection system can keep the nitrogen concentration above 98%. It can monitor the nitrogen concentration in real time and replenish it in time, fundamentally avoiding the risk of combustion and explosion of power batteries used in electric buses. The thermal runaway risk prevention methods are now being commercialized.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.