-

092025-12

How to Optimize the Cost of High-Voltage Wiring Harnesses in Battery Electric VehiclesThis article provides a practical summary of experience in HV wiring harness cost optimization. It explains the cost structure of HV wiring harnesses and their material composition, and further introduces a series of cost-reduction approaches—including HV system architecture optimization, routing optimization, material optimization, platform and standardization design. The goal is to offer valuable reference solutions for engineers and OEMs striving for cost competitiveness.Learn More >>

How to Optimize the Cost of High-Voltage Wiring Harnesses in Battery Electric VehiclesThis article provides a practical summary of experience in HV wiring harness cost optimization. It explains the cost structure of HV wiring harnesses and their material composition, and further introduces a series of cost-reduction approaches—including HV system architecture optimization, routing optimization, material optimization, platform and standardization design. The goal is to offer valuable reference solutions for engineers and OEMs striving for cost competitiveness.Learn More >> -

032025-12

Liquid Cooling Server ComponentsLiquid-cooled servers utilize specialized components to efficiently manage heat in high-density computing environments. Key elements include cold plates for direct chip heat transfer, water-based or non-water-based coolants, quick disconnect couplings for easy maintenance, cooling distribution units (CDUs), primary-side cooling sources, immersion cooling tanks, and piping and valve assemblies. This article details their operating principles, types, performance specifications, and technological trends, providing a comprehensive overview of modern liquid cooling solutions for data centers.Learn More >>

Liquid Cooling Server ComponentsLiquid-cooled servers utilize specialized components to efficiently manage heat in high-density computing environments. Key elements include cold plates for direct chip heat transfer, water-based or non-water-based coolants, quick disconnect couplings for easy maintenance, cooling distribution units (CDUs), primary-side cooling sources, immersion cooling tanks, and piping and valve assemblies. This article details their operating principles, types, performance specifications, and technological trends, providing a comprehensive overview of modern liquid cooling solutions for data centers.Learn More >> -

262025-09

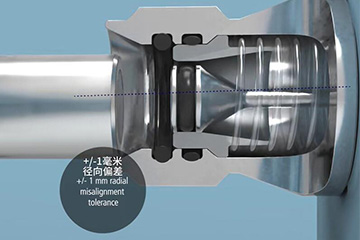

UQD Blind-Mate Connectors: Driving Liquid Cooling StandardizationBlind-mate UQDs (UQDB) represent the future of liquid cooling, offering higher automation, reduced human error, and superior system uptime. As AI and high-performance computing demand continuous operations, blind-mate connectors are expected to become the mainstream choice, while hand-mate products will remain in cost-sensitive applications.Learn More >>

UQD Blind-Mate Connectors: Driving Liquid Cooling StandardizationBlind-mate UQDs (UQDB) represent the future of liquid cooling, offering higher automation, reduced human error, and superior system uptime. As AI and high-performance computing demand continuous operations, blind-mate connectors are expected to become the mainstream choice, while hand-mate products will remain in cost-sensitive applications.Learn More >> -

102025-09

Electrical Contact Reliability of EV Connectors and the Application of Copper MaterialsCopper is essential for automotive connectors, affecting conductivity, strength, and reliability. This study reviews contact design, failure mechanisms, material selection, and manufacturing/testing processes. Optimized copper alloys enhance electrical performance, thermal stability, and wear resistance, ensuring long-term reliability for conventional, new energy, and high-frequency automotive and electronic applications.Learn More >>

Electrical Contact Reliability of EV Connectors and the Application of Copper MaterialsCopper is essential for automotive connectors, affecting conductivity, strength, and reliability. This study reviews contact design, failure mechanisms, material selection, and manufacturing/testing processes. Optimized copper alloys enhance electrical performance, thermal stability, and wear resistance, ensuring long-term reliability for conventional, new energy, and high-frequency automotive and electronic applications.Learn More >> -

252025-07

Revealing the MSD Service Disconnect: A Key to Electrical Safety!The Manual Service Disconnect (MSD) serves as a critical safety device in electric vehicle and new energy high-voltage systems, providing protection against short circuits and overloads during maintenance. MSDs incorporate high-voltage fuses and interlock functions to ensure operational safety. Key performance criteria include UL94 V-0 flame resistance, IP67/IP6K9K ingress protection, tool-free manual disconnection, and a locking mechanism to prevent misoperation.Learn More >>

Revealing the MSD Service Disconnect: A Key to Electrical Safety!The Manual Service Disconnect (MSD) serves as a critical safety device in electric vehicle and new energy high-voltage systems, providing protection against short circuits and overloads during maintenance. MSDs incorporate high-voltage fuses and interlock functions to ensure operational safety. Key performance criteria include UL94 V-0 flame resistance, IP67/IP6K9K ingress protection, tool-free manual disconnection, and a locking mechanism to prevent misoperation.Learn More >> -

162025-07

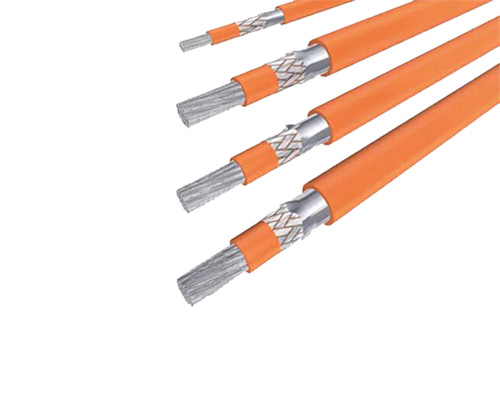

Optimization of Shielding Structure in EV High-Voltage CablesAs electric vehicles continue to gain traction worldwide, ensuring the reliability of high-voltage components becomes a central focus of vehicle design. Among these, high-voltage cables serve as the critical arteries for energy transmission. This article presents a comparative analysis of various shielding structures used in high-voltage cables and highlights a new design—an extruded semi-conductive layer combined with tinned copper braid shielding. The new structure significantly improves cable lifespan and shielding performance without compromising flexibility or increasing production costs.Learn More >>

Optimization of Shielding Structure in EV High-Voltage CablesAs electric vehicles continue to gain traction worldwide, ensuring the reliability of high-voltage components becomes a central focus of vehicle design. Among these, high-voltage cables serve as the critical arteries for energy transmission. This article presents a comparative analysis of various shielding structures used in high-voltage cables and highlights a new design—an extruded semi-conductive layer combined with tinned copper braid shielding. The new structure significantly improves cable lifespan and shielding performance without compromising flexibility or increasing production costs.Learn More >>

- Home

-

Solutions

High Voltage Wiring Harness SolutionGuchen Electronics is a one-stop source for electric vehicle high voltage cable harness assembly, low voltage cable harness assembly and electrical connectors.

ESS Battery Connection SolutionsWe offer customized connection solutions for all your BESS requirements. From front to rear connection, we have the right solution for you. Besides that, we have a team of highly trained engineers and technicians who can solve any connection issue that you may have.

ESS Battery Connection SolutionsWe offer customized connection solutions for all your BESS requirements. From front to rear connection, we have the right solution for you. Besides that, we have a team of highly trained engineers and technicians who can solve any connection issue that you may have. EV High Voltage Interconnection SolutionHigh Voltage Interconnection Solutions are the connectors used to connect the high voltage components in Electric Vehicles. Guchen offers a wide range of High Voltage Connectors for EV, HEV and PHEV applications.

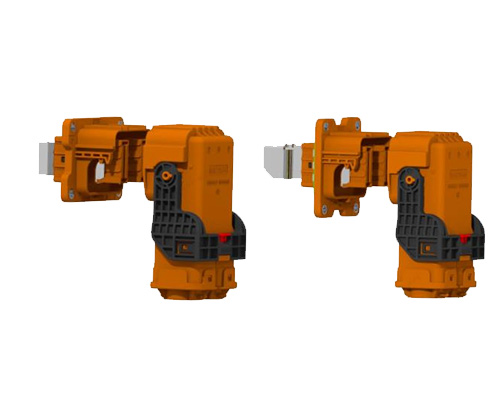

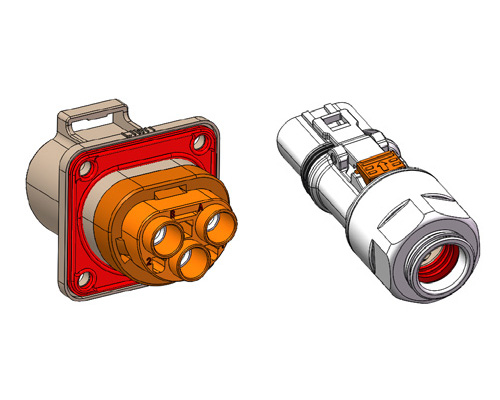

EV High Voltage Interconnection SolutionHigh Voltage Interconnection Solutions are the connectors used to connect the high voltage components in Electric Vehicles. Guchen offers a wide range of High Voltage Connectors for EV, HEV and PHEV applications. EV Charging SolutionGuchen Electronics offers OEM/ODM, customization services, and has expertise in providing charging solutions for both commercial and residential customers.

EV Charging SolutionGuchen Electronics offers OEM/ODM, customization services, and has expertise in providing charging solutions for both commercial and residential customers.

-

Products

EV HV ConnectorsElectric vehicle connectors supplied by Guchen Electronics are with excellent shielding, fast safe easy assembling, wide wire section options, compact design and multi positions connectors options. In order to meet different requirements, we provide our customers with various types of quality HV connectors, widely used in the fields of automotive electronics.EV HV Wiring HarnessGuchen Electronics is a professional manufacturer of HV assembled wiring harnesses for electric passenger cars and commercial vehicles. We always pay attention to the quality of HV cables & connectors, and provide global EV manufacturers with high quality products and excellent service.EV HV CableWe have a wide range of high voltage cables for passenger car and commercial vehicles like bus, truck, coach etc. Guchen EV HV cables can handle high currents and high voltage. They are high temperature resistant, soft, and with variable options (2.5mm²~120mm² sizes, shielded or unshielded, copper or aluminum cable options). Guchen cables are full customizable to meet different EV requirements.EV Charging Connectors (Socket & Plug)We can offer premium quality type 2 charging gun, CCS2 DC charging plug, CCS2 charging socket vehicle inlet etc. Guchen EV Charging Connectors are built with precision and reliability in mind. All of our EV charging plugs and sockets are made from high-quality materials engineered to withstand daily use in public charging stations. We've rigorously tested them to meet the latest standards for safety, charging speed and reliability. Guchen Electronic aims to be a leading supplier of charging solutions as electric vehicles become more prevalent worldwide. Please contact us to learn more about our EV charging connectors.Energy Storage ConnectorGuchen Electronics is specialized in designing and manufacturing of electric vehicle high voltage connectors (with various specifications and features), HV wire harness & cables, EV charging equipment, and HV connectors for Battery Energy Storage System (BESS).Liquid Cooling Quick DisconnectsGuchen Electronics Liquid Cooling Quick Disconnects – Efficient, Reliable, and Future-Ready! Optimize your data center cooling with Guchen Electronics’ Liquid Cooling Quick Disconnects. Designed for high-performance thermal management, our connectors ensure rapid, leak-free connections, effortless maintenance, and superior durability under extreme conditions. Supporting high flow rates and a variety of cooling fluids, they are engineered for seamless integration with liquid-cooled racks, servers, and high-density computing systems.

-

Blog

Company BlogGuchen Electronics is a professional China factory for electric vehicle connectors, high voltage cable assemblies, EV charging equipment and energy storage connectors. We provide all kinds of products with high quality and competitive price.

Industry BlogHere you can learn about the global electric vehicle industry, news, reviews and analysis about electric vehicle industry trends, technologies and manufacturers.

Industry BlogHere you can learn about the global electric vehicle industry, news, reviews and analysis about electric vehicle industry trends, technologies and manufacturers. ExhibitionsGuchen Electronics attends various exhibitions yearly, including Electric Vehicle Expo which has become a world-famous event. As one of the best EV HV connector manufacturers, Guchen Electronics has attracted hundreds of suppliers and buyers from all over the world during the exhibitions.

ExhibitionsGuchen Electronics attends various exhibitions yearly, including Electric Vehicle Expo which has become a world-famous event. As one of the best EV HV connector manufacturers, Guchen Electronics has attracted hundreds of suppliers and buyers from all over the world during the exhibitions. Technical SupportGuchen provides one-stop technical supports relating to HV connectors, cable assemblies, and energy storage connectors. We have strong expertise in different technologies not only limited to power electronics. We have provided the standard level of services for our customers during the whole process from initial product design, building to mass production and routine maintenance.

Technical SupportGuchen provides one-stop technical supports relating to HV connectors, cable assemblies, and energy storage connectors. We have strong expertise in different technologies not only limited to power electronics. We have provided the standard level of services for our customers during the whole process from initial product design, building to mass production and routine maintenance.

-

About Us

About UsAbout usGuchen Electronics is a professional manufacturer and custom solution provider of electric vehicle connection system and ESS battery connection system. We are located in Shenzhen, China. Our international business covers more than 70 countries around the world. With many years' experience in the field, we can provide OEM products with high quality, good price and on time delivery. Welcome to contact us if you are interested in any of our products.

Quality AssuranceGuchen Electronics is a manufacturer of all kinds of high voltage connectors. Our products include, high voltage interlock connectors, low/high current HV connectors and cable assembly which are compliant with international standards. We have an excellent team and advanced production equipment to meet market demands.

Quality AssuranceGuchen Electronics is a manufacturer of all kinds of high voltage connectors. Our products include, high voltage interlock connectors, low/high current HV connectors and cable assembly which are compliant with international standards. We have an excellent team and advanced production equipment to meet market demands. ServiceNo matter your business is large or small, OEM, ODM and OBM orders are all available. We can provide you with the best pre-sale and after-sale services, to ensure that your orders are completed smoothly in time. Guchen connectors covers all kinds of types with OEM services. We firmly believe that it is the best way to establish a win-win cooperation. Guchen EV HV connectors is your excellent choice. The reasons why Guchen EV HV connectors is your competent partner: 1) Good quality + Competitive price + Professional service 2) Short delivery date 3) Reliable and stable after-sale service

ServiceNo matter your business is large or small, OEM, ODM and OBM orders are all available. We can provide you with the best pre-sale and after-sale services, to ensure that your orders are completed smoothly in time. Guchen connectors covers all kinds of types with OEM services. We firmly believe that it is the best way to establish a win-win cooperation. Guchen EV HV connectors is your excellent choice. The reasons why Guchen EV HV connectors is your competent partner: 1) Good quality + Competitive price + Professional service 2) Short delivery date 3) Reliable and stable after-sale service

- Contact