Irradiation Process in the Production of HV Cross-linked Polyethylene Cables, Principles & Advantages

Cross-linked polyethylene (XLPE) cable is a high-voltage cable that is cross-linked using a special process. The cross-linking treatment can improve the insulation performance and heat resistance of the cable, making the cable more stable and reliable during use. Irradiation XLPE cable uses radiation rays for cross-linking treatment and has high performance and advantages.

1. After irradiation, the material molecular structure of the insulation layer and protective sheath changes into a three-dimensional network structure. Its high temperature resistance level is higher than that of ordinary cables, with a temperature resistance level of up to 125°C. The carrying capacity becomes larger, increasing by 1.2 to 1.6 times, which greatly improves the cable's ability to withstand overload.

2. The insulation resistance is larger and safer.

3. Longer service life, environmentally friendly and safe, because the materials are all halogen-free.

4. The strength, elasticity, etc. of the cable are significantly improved, and the tensile and wear resistance are also improved.

5. Due to improved performance, the price is also relatively high.

◆ Low density: Irradiation cross-linked PE cables have a density which is less than half that of regular PE cables, making them lighter and easier to install. They are also easier to transport because they don't weigh as much as regular PE cables do.

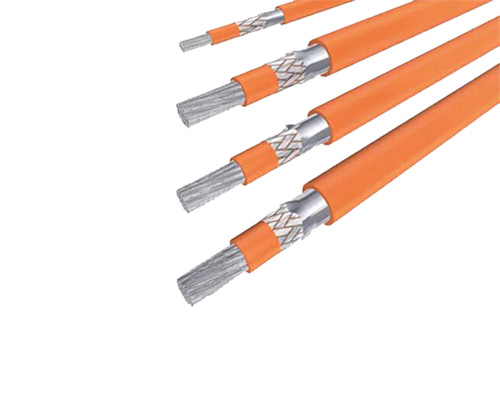

◆ Heat resistance: Irradiated cross-linked PE cables can withstand temperatures up to 125 degrees Celsius without losing their properties or shape. This makes them ideal for use in electric vehicle applications. Taking Guchen EV XLPE shielded HV cable for example, the 16mm2 cable is most widely used in mini electric cars; the 50sqmm & 70sqmm cable for electric commercial vehicle interconnection systems.

Due to the irradiation process, irradiated PE cables have excellent thermal stability and chemical resistance. They also have a high level of flexibility that enables them to resist crushing or twisting damage during installation and use. These qualities make them ideal for use as power supply cables in electrical vehicles where they are subject to high temperatures and vibration caused by the different driving conditions.

Irradiation—Principles

The production principle is to use the high-energy electron beam of the electron irradiation accelerator to irradiate the cable insulation layer and protective layer. The original relatively independent chain structure of the plastic body becomes a three-dimensional network structure connected with the same layer and connected layer by layer.Irradiation—Functions & Advantages

Converting insulation from thermoplastic to thermosetting materials greatly improves the mechanical and physical properties of wire and cable products, improves flame retardancy without melting, heat resistance, improves stability, and service life, etc.1. After irradiation, the material molecular structure of the insulation layer and protective sheath changes into a three-dimensional network structure. Its high temperature resistance level is higher than that of ordinary cables, with a temperature resistance level of up to 125°C. The carrying capacity becomes larger, increasing by 1.2 to 1.6 times, which greatly improves the cable's ability to withstand overload.

2. The insulation resistance is larger and safer.

3. Longer service life, environmentally friendly and safe, because the materials are all halogen-free.

4. The strength, elasticity, etc. of the cable are significantly improved, and the tensile and wear resistance are also improved.

5. Due to improved performance, the price is also relatively high.

The Advantages of Irradiated Cross-linked Polyethylene Cables Include:

◆ High tensile strength: The strength of these cables is about five times higher than that of regular polyethylene (PE) cables. This makes them suitable for heavy duty applications such as those in EVs. The high tensile strength also means that the cables have excellent resistance to abrasion, impact and pressure.◆ Low density: Irradiation cross-linked PE cables have a density which is less than half that of regular PE cables, making them lighter and easier to install. They are also easier to transport because they don't weigh as much as regular PE cables do.

◆ Heat resistance: Irradiated cross-linked PE cables can withstand temperatures up to 125 degrees Celsius without losing their properties or shape. This makes them ideal for use in electric vehicle applications. Taking Guchen EV XLPE shielded HV cable for example, the 16mm2 cable is most widely used in mini electric cars; the 50sqmm & 70sqmm cable for electric commercial vehicle interconnection systems.

Due to the irradiation process, irradiated PE cables have excellent thermal stability and chemical resistance. They also have a high level of flexibility that enables them to resist crushing or twisting damage during installation and use. These qualities make them ideal for use as power supply cables in electrical vehicles where they are subject to high temperatures and vibration caused by the different driving conditions.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.