Everything You Want to Know about High Voltage Interlock Loop

What is HVIL?

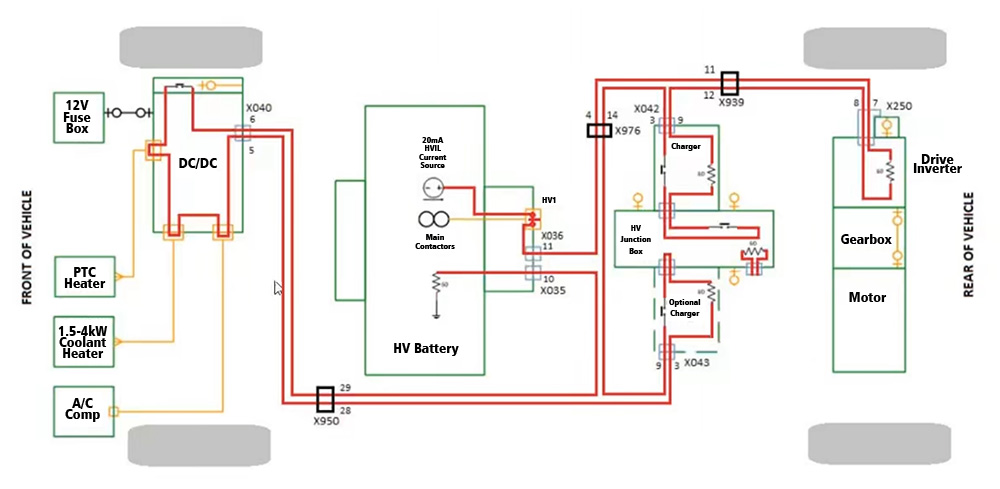

High voltage interlock loop (HVIL) is a safety device used in high voltage systems, including the electrical safety of the battery pack, wire harnesses, connectors, DC-DC, motor controller, power distribution box and protective cover, etc.. It is basically a circuit that monitors the state of high voltage connectors in electric and hybrid vehicles and automatically disconnects the connector from its supply if there is an abnormal condition.In the ISO international standard "ISO 6469-3:2001, Electric Road vehicles - Safety Specifications - Part 3: Protection of Persons Against Electric Hazards", it is stipulated that the high-voltage components on the EV should have high-voltage interlock device.

The Function of HVIL

The loose connection of the high-voltage circuit is one of the reasons for the power loss of new energy vehicles. Another risk of electric vehicles is that human mis-operation of manually disconnects the high-voltage connector during system operation. Once the disconnection happening, the entire loop voltage is applied across the connector terminals. The high-voltage connector itself does not have the ability to break, so the voltage generates a strong arc between the plug connector and header connector, which may cause damage to personnel and equipment around the breakpoint.The main functions of the dedicated design of high-voltage interlock loop can

1.Ensure the integrity and continuity of the entire high voltage circuit, so that the HV system works in a closed environment to improve safety.

2.Start security protection when the high voltage system is disconnected or its integrity is damaged during operation.

3.Prevent arcing damage to high voltage terminals caused by live plugging and unplugging of high voltage connectors.

How Does HVIL Work?

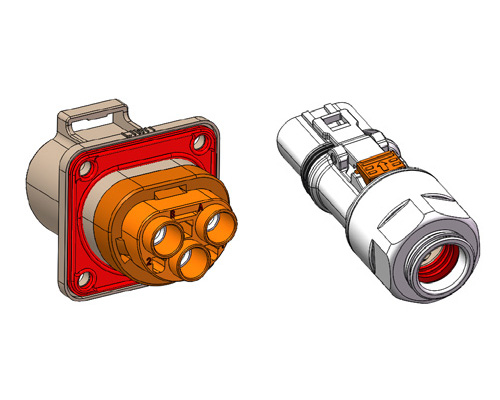

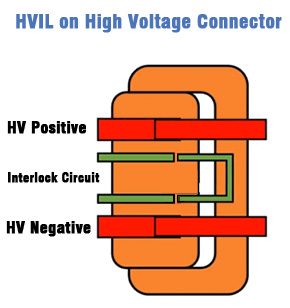

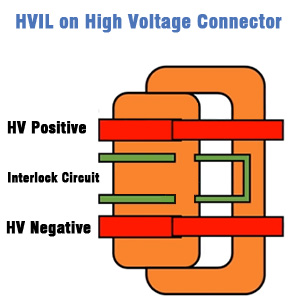

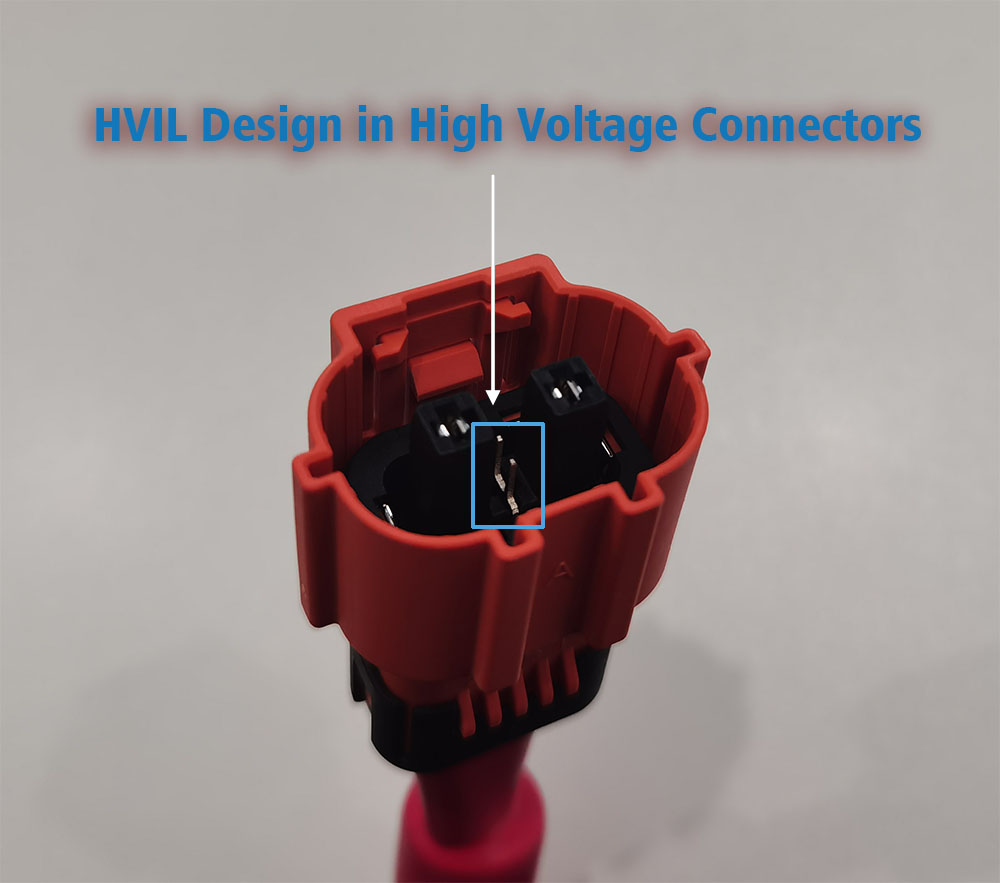

The high-voltage interlock protection device detects the integrity and continuity of the high-voltage circuit through a low-voltage signal. Specifically, it uses a small current of 12V to confirm the integrity of the entire high-voltage electrical system, and judge whether the plugs on the high-voltage circuit are installed in place and abnormally loose. All high-voltage components and connectors must be installed in place without short circuit or open circuit.As shown in the figure, there are a pair of small pins on the high-voltage plug and header, which are the lines of the high-voltage interlock system.

|

|

|

|

Electric vehicles usually have several groups of high voltage interlock loops, while some EVs have only one interlock loop. Some interlock signals are sent by the VCU, and some other are sent by the BMS. When there is a virtual connection or disconnection or a short-circuit fault in the HVIL, an early warning will be issued to disconnect the high voltage battery DC power.

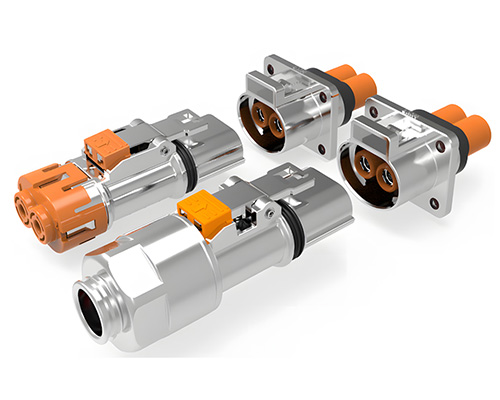

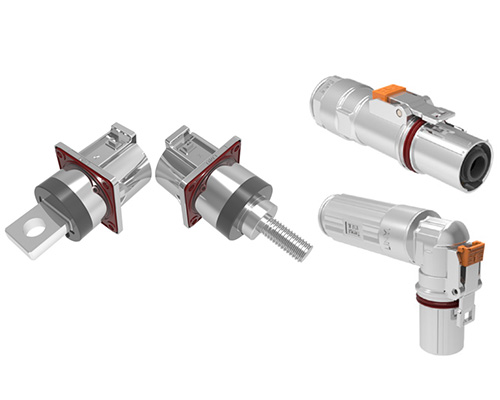

HVIL Connectors

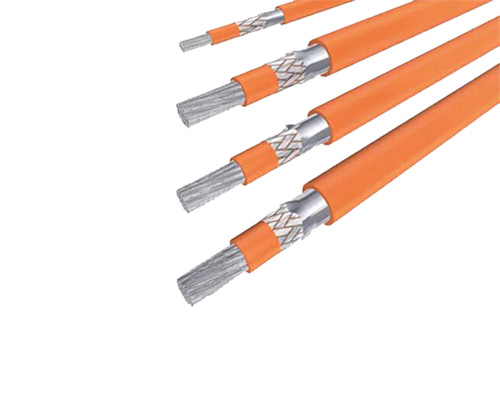

High-voltage interlock connectors need to be used with batteries, motors, electric controls and high-voltage systems. HVIL design ensures the safety of the EV connector in use. In addition to the high-voltage connection between two devices, it can also connect a device and a ground point, which can effectively control the voltage between two devices or prevent accidental contact.HVIL connectors are divided into male and female connectors based on different positions. Male and female high-voltage connectors are generally used together to form a complete connection system. Different high voltage components are connected with each other by means of EV wire harness(consisting of connectors and cables) through mechanical means such as screws or bolts to ensure electrical contact between them.

HVIL Connectors are characterized by:

◆ Wide range of operating temperature range from -40℃ to +140℃; The maximum operating voltage of HVIL connectors is up to 1000V. High-voltage interlock connectors are used in many different EVs. Because of the different working environments and operating conditions of these vehicles, the temperature range requirements are relatively high.

◆ Reliable sealing structure. IP6K9K waterproof level. Its sealing structure can prevent water vapor from entering the connector cavity, which ensures good insulation performance under high voltage.

◆ Structure to prevent shedding: High-voltage interlock connectors must be fixed with bolts or nuts when designing. This ensures reliable electrical contact between each pair of contacts and prevents them from being damaged due to external impacts during EV operation.

The answers to other questions that readers may be concerned about are as follows:

(1) Cable Management & Routing of 12V Wires:

The 12V HVIL wires can be routed alongside the high voltage (HV) lines within the same cable assembly. To protect them and reduce interference, these wires can be fully encased with the HV cables using shielding or corrugated tubing. This method ensures that the HVIL wires remain secure and insulated from potential environmental hazards while running parallel to the HV conductors.

(2) HVIL Signal Degradation:

The HVIL typically operates using a low-voltage signal (12V) with a square wave format. The risk of signal degradation is minimal when proper shielding and grounding practices are followed. However, any degradation usually results from electromagnetic interference (EMI) from the HV lines. Therefore, adequate shielding of both the HV and HVIL wires is crucial to maintaining signal integrity.

(3) Maximum Length for HVIL Signal Lines:

The maximum length of HVIL signal lines can vary depending on the system design and the quality of the components used. Generally, HVIL signal lines can be extended up to several meters without issues, provided the resistance and capacitance of the wire are within acceptable limits. However, it's essential to consult with the system's specifications or perform testing for the exact length limits in your specific application.

(4) Maximum "Loop" Configuration:

The maximum loop configuration for the HVIL depends on the overall system design and the resistance of the wiring. The loop must be designed to detect any break or fault across the entire length of the system. Therefore, while there's no strict "maximum" loop length, it's essential to ensure that the total resistance does not exceed the detection threshold of the HVIL monitoring system. The system should still be able to detect an open circuit if a fault occurs anywhere along the loop.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.