Why Electro Tin Plating is Essential for Copper Busbars in BESS?

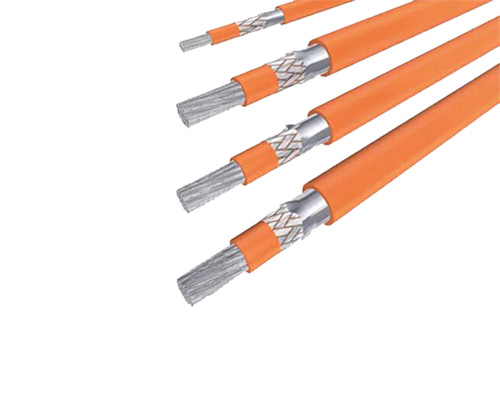

Copper busbars are critical components in Battery Energy Storage Systems (BESS) due to their excellent conductivity, mechanical strength, and reliability. These qualities make copper the preferred material for efficiently managing high current flow in power distribution systems. However, despite its superior conductivity, pure copper is not without challenges, particularly regarding its susceptibility to oxidation. To mitigate these issues, electro tin plating has emerged as a widely adopted solution. This article explores why tin plating is essential for copper busbars in BESS applications.

For components like busbars, where low resistance and consistent conductivity are critical, this degradation can cause energy losses, overheating, and even system failure. Consequently, addressing copper's vulnerability to oxidation is a priority for ensuring reliable and efficient performance in BESS.

◆ Anti-Oxidation Properties

Tin plating creates a robust protective layer that prevents oxygen and moisture from reaching the copper underneath. Unlike pure copper, the tinned surface does not oxidize readily, maintaining its integrity and conductivity over time.

◆ Cost-Effectiveness

While gold and silver provide superior conductivity, their high cost makes them impractical for large-scale applications like busbars, which often have substantial surface areas. Tin, on the other hand, offers a conductivity that is close to silver at a fraction of the cost, making it a highly economical option.

◆ Good Electrical Conductivity

Tin is an excellent conductor of electricity, ensuring that the busbar's performance remains efficient. Although it does not surpass pure copper in conductivity, the thin layer of tin does not significantly impede the flow of current, making it an ideal compromise between protection and performance.

◆ Ease of Application

Electro tin plating is a straightforward and scalable process, allowing manufacturers to apply it efficiently to busbars of various sizes and shapes. Its versatility and reliability make it a preferred method for improving copper’s durability.

◆ Corrosion Resistance

In addition to preventing oxidation, tin plating enhances resistance to other forms of corrosion, such as those caused by exposure to chemicals or varying environmental conditions. This durability is particularly important in BESS installations, which often operate in challenging environments.

As energy storage systems continue to play a pivotal role in advancing renewable energy solutions, ensuring the durability and reliability of their components, like copper busbars, becomes even more crucial. Electro tin plating is a simple yet essential step in achieving these goals, ensuring that BESS installations operate at peak efficiency for years to come.

The Problem with Pure Copper: Oxidation and Its Effects

While pure copper boasts excellent electrical conductivity, its exposure to air leads to a significant drawback: oxidation. When unprotected copper, such as that used in copper bus bar connectors, is exposed to oxygen and moisture, it forms a layer of copper oxide, commonly known as verdigris. This greenish layer is not only unsightly but also detrimental to the busbar’s performance. Verdigris acts as an insulating layer, increasing electrical resistance at the surface and reducing overall conductivity.For components like busbars, where low resistance and consistent conductivity are critical, this degradation can cause energy losses, overheating, and even system failure. Consequently, addressing copper's vulnerability to oxidation is a priority for ensuring reliable and efficient performance in BESS.

Electroplating as a Protective Solution

To prevent oxidation and maintain optimal conductivity, copper busbars are commonly electroplated with a protective layer of metal. Electroplating forms a uniform coating on the surface of the copper, acting as a barrier between the base material and the surrounding environment. Various metals can be used for this purpose, including tin, nickel, gold, and silver. Each material offers unique advantages, but cost-effectiveness and conductivity often drive the selection process.Why Tin Plating?

Among the electroplating options, tin stands out as the most practical and widely used choice for copper busbars in BESS. Here’s why:◆ Anti-Oxidation Properties

Tin plating creates a robust protective layer that prevents oxygen and moisture from reaching the copper underneath. Unlike pure copper, the tinned surface does not oxidize readily, maintaining its integrity and conductivity over time.

◆ Cost-Effectiveness

While gold and silver provide superior conductivity, their high cost makes them impractical for large-scale applications like busbars, which often have substantial surface areas. Tin, on the other hand, offers a conductivity that is close to silver at a fraction of the cost, making it a highly economical option.

◆ Good Electrical Conductivity

Tin is an excellent conductor of electricity, ensuring that the busbar's performance remains efficient. Although it does not surpass pure copper in conductivity, the thin layer of tin does not significantly impede the flow of current, making it an ideal compromise between protection and performance.

◆ Ease of Application

Electro tin plating is a straightforward and scalable process, allowing manufacturers to apply it efficiently to busbars of various sizes and shapes. Its versatility and reliability make it a preferred method for improving copper’s durability.

◆ Corrosion Resistance

In addition to preventing oxidation, tin plating enhances resistance to other forms of corrosion, such as those caused by exposure to chemicals or varying environmental conditions. This durability is particularly important in BESS installations, which often operate in challenging environments.

Alternative Plating Options

While tin plating is the most common choice, alternatives like nickel, gold, and silver are sometimes used for specialized applications. Gold and silver offer superior conductivity but are prohibitively expensive for large-scale applications. Nickel plating, though more affordable, does not match tin's combination of conductivity, corrosion resistance, and cost-efficiency.Conclusion

Electro tin plating is not just a protective measure but a necessity for ensuring the long-term performance of copper busbars in Battery Energy Storage Systems. By preventing oxidation, maintaining electrical conductivity, and offering cost-effective protection, tin plating addresses the key challenges associated with pure copper busbars. Its balance of affordability and efficiency makes it the preferred choice for manufacturers and engineers seeking to optimize BESS performance.As energy storage systems continue to play a pivotal role in advancing renewable energy solutions, ensuring the durability and reliability of their components, like copper busbars, becomes even more crucial. Electro tin plating is a simple yet essential step in achieving these goals, ensuring that BESS installations operate at peak efficiency for years to come.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.