Touch-safe Technologies Used in High Voltage Connectors

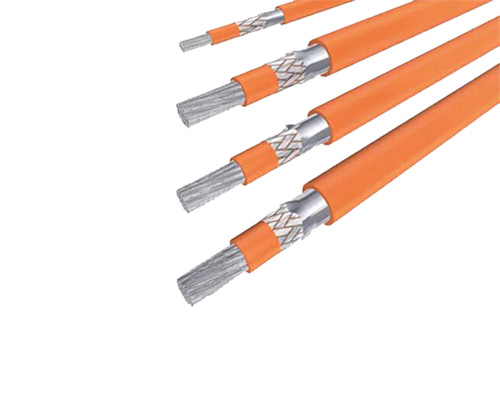

◆ It is used to connect the vehicle's electrical systems with batteries, starter motors, and other components. The design of this connector must be robust enough to withstand vibration and mechanical shock without breaking down.

◆ It is to provide an interface between metal parts that are energized by relatively large voltages or currents. It also provides an electrical connection between these parts and circuits in the vehicle that can protect the electronics from damage due to high voltage or current.

High voltage connectors must be reliable and safe in order to ensure that they do not create a hazard for technicians who work with them every day. They are designed with many safety features to prevent short circuits and other conditions that can cause damage or injury in vehicles.

Error prevention work system (EPWS) is used in the design of HV connector. An EPWS is a systematic approach for designing products that minimize human error during assembly processes. When designing EV HV connectors, engineers use some safety designs to increase connector reliability and prevent operators from getting injured when accidental touching of live contacts.

These Touch-safe Designs Include:

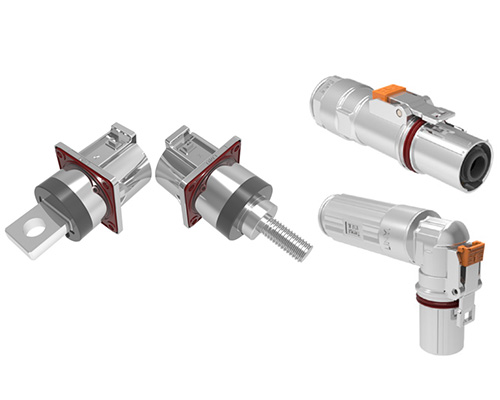

1) High Voltage Interlock Loop

A high voltage interlock loop is a safety device that detects whether the connector and terminal are properly connected. It is an integral part of the high voltage connector, and its purpose is to prevent arcing or sparking when the voltage between the terminals comes close to zero. The connector consists of two main parts: a male and female terminal set and an insulating tube. The high voltage interlock loop consists of a pair of contacts which are located in a special recess in each terminal of both sets. These contacts are connected by an electrical lead to a control circuit inside the connector housing. When the connector is not fully seated, these contacts remain open and do not complete the circuit until they touch each other when fully seated on the mating body.---The high voltage interlock loop prevents inadvertent reconnection of a high voltage connector that has been disconnected for maintenance, inspection or repair. This feature is provided by a separate and independent electrical circuit which supplies power to the disconnecting switch and to all other parts of the circuit except the high voltage cable itself and its connections.

---It prevents the application of voltage to a connector without electrical continuity being present at the terminations. If there is no continuity, the loop will prevent the application of voltage until it is corrected. This ensures that no damage can be done to equipment or personnel.

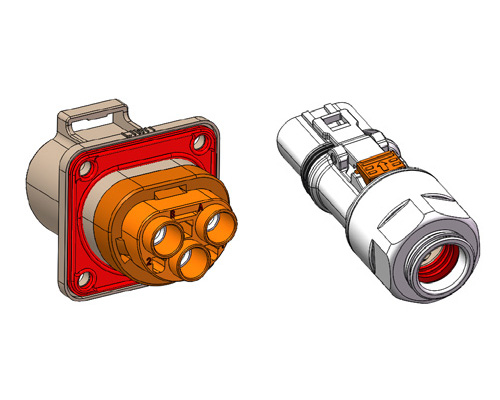

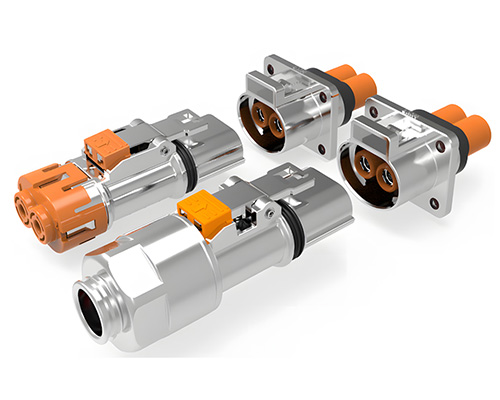

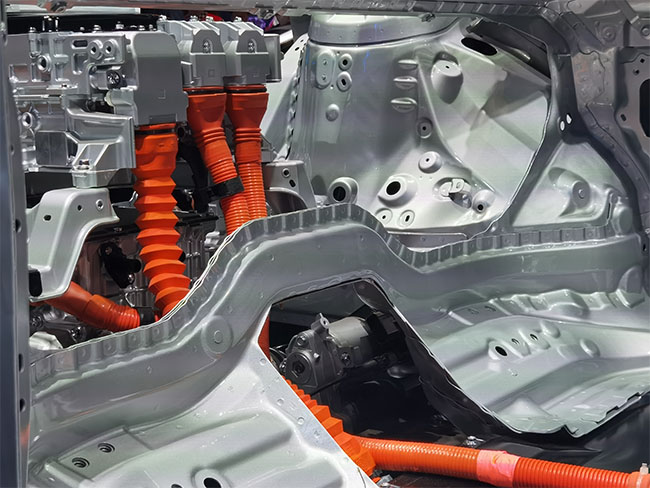

2) Outer Insulating Protective Jacket

The insulating protective jacket provides protection to personnel from accidental contact with the high voltage insulated conductors in the connector. In addition, it provides protection against mechanical damage resulting from handling and installation operations. The cover can have a variety of shapes including circular, square, octagonal and rectangular depending on the application requirements such as size and shape of terminals being covered, cost and ease of molding etc.

3) Finger-proof Terminals

Finger-proof terminals are designed with insulating material between the electrical metal conductors and potential human interfaces. It is regarded as a secondary safety design to prevent human fingers from touching the metal contacts at the electric vehicle high voltage power systems. Guchen HVIL plastic connectors feature a patented insulating protective cover design around the metal terminals, which effectively protects the operator by eliminating unintended finger contact with connector pins.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.