Wire Harness Industry: Technological Innovation Drives the Future of Intelligence, Lightweighting, and Sustainability

In today's era, key sectors such as automotive, communications, and industrial fields are growing at a remarkable pace, like high-speed trains propelling the related industries forward. As the “nervous system” of these sectors, the wire harness industry has inevitably been swept into the wave of technological innovation. Traditional design and production methods in the EV wire harness sector have gradually shown signs of fatigue in the face of ever-increasing market demands, struggling to keep up. As a result, smart technology, lightweight materials, and sustainability have emerged as the leading forces guiding the industry forward, creating a future filled with endless possibilities.

1. Intelligent Technology: The Digital Engine Powering Efficiency Gains

◆ AI Empowerment: Precision-Driven Design Optimization

Artificial intelligence is deeply embedded in the wire harness design process, like a stone thrown into a calm lake, creating a wave of disruptive change. With the help of advanced AI algorithms, the system behaves like an ever-vigilant and quick-thinking designer, capable of generating massive design proposals in the blink of an eye. These designs undergo precise simulations to evaluate and optimize layouts in terms of electrical performance, space utilization, and cost-effectiveness from multiple dimensions. This process installs a turbocharger on the design engine, significantly shortening the lengthy design cycle and reducing costly trial-and-error processes, making the design more efficient and accurate—as though performed by a smooth, high-precision machine.◆ Automation Takes the Lead, Accelerating Production

Robots and automated equipment have been widely adopted in the industry, fundamentally rewriting the traditional wire harness production model. Today’s automated production lines are like a well-trained, disciplined industrial army, with each stage tightly coordinated and methodically organized. These systems can effortlessly handle tasks such as wire cutting, crimping, and assembly—previously complex and heavily reliant on manual labor. In this process, production efficiency has increased exponentially, transforming from the slow pace of a snail to the swift flight of an eagle. The consistency in product quality is also rock-solid, providing a strong foundation for mass, high-quality production and acting as a protective barrier for product quality.◆ Intelligent Inspection: A New Era of Quality Control

The fusion of machine vision and AI technology has injected magical power into the wire harness quality inspection process, leading to a qualitative leap. The intelligent inspection system functions like a pair of “eagle eyes,” capable of detecting even the most subtle defects in the wire harness. Whether it's a critical electrical issue like short circuits or open circuits, or overlooked interface flaws, no detail escapes its scrutiny. This technology dramatically improves inspection efficiency and accuracy, replacing slow, error-prone human eye inspections with a high-speed, precision scanning system, ensuring that every wire harness that reaches the market meets strict quality standards.

2. Lightweighting: Material Innovation Driving Performance Advances

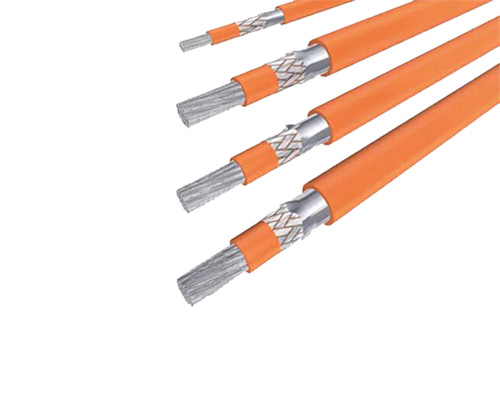

◆ Lightweight Materials: Leading the Charge

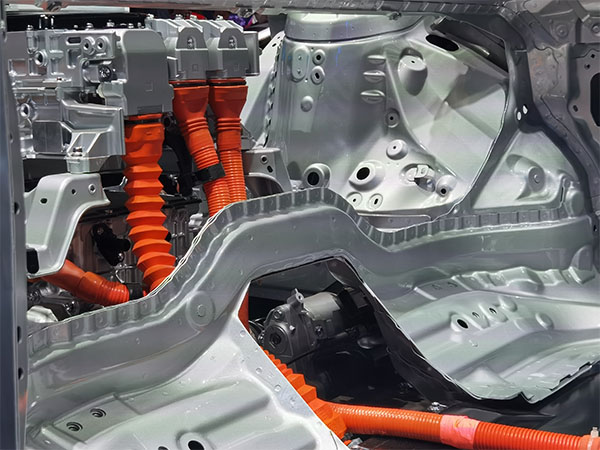

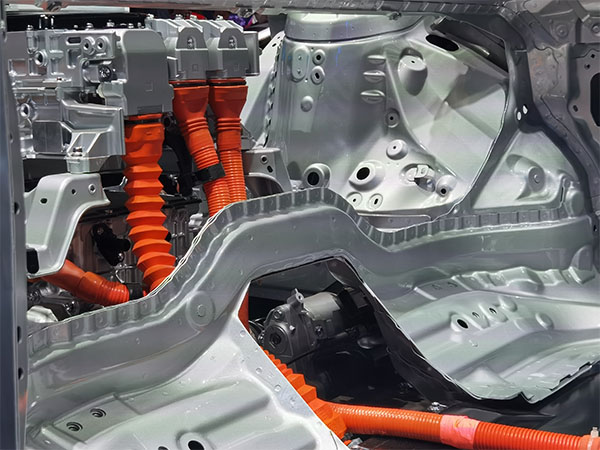

Lightweight materials such as aluminum alloy and carbon fiber are rapidly gaining market share, disrupting the traditional dominance of copper. These materials, with their low density and high strength, play a key role in reducing the weight of wire harnesses. Imagine a heavy wire harness dressed in lightweight armor—while shedding weight, these materials significantly improve both the electrical and mechanical performance of the product. They inject new energy into the efficient operation of devices, much like equipping an athlete with a pair of lightweight, high-performance running shoes that allow them to race forward on a more efficient track.◆ Structural Optimization: Precisely Reducing Weight

The high voltage wire harness industry is on an intense quest to optimize structure and layout, constantly seeking the most efficient balance between material input and functional output. In this process, engineers act like skilled artisans, carefully crafting every structural detail. Ingenious design reduces unnecessary material use—like tailoring a garment, removing excess fabric while maintaining the harness’s performance. This enables lightweighting without compromising functionality, giving the wire harness a new agility, allowing it to navigate complex environments freely.◆ Miniaturized Connectors: Opening New Possibilities

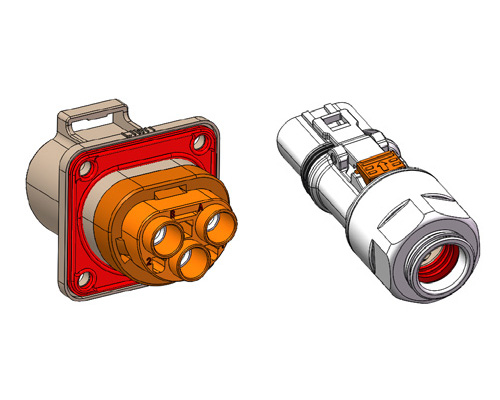

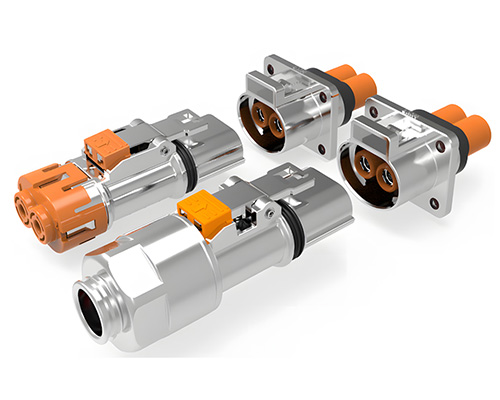

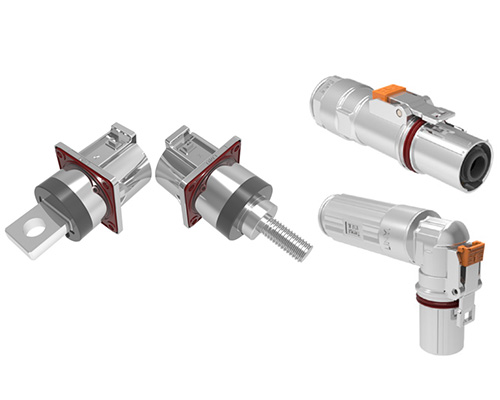

Smaller, more compact high voltage connector designs have rapidly become the new industry trend. These mini connectors not only reduce the volume and weight of the wire harness, but they also perfectly align with the current trend of miniaturizing and lightweighting devices. They create ample room for the slimmed-down designs of electronic products, opening a gateway to new creative possibilities. These HV connectors enable products to achieve greater portability and sophistication, enhancing the user experience.

3. Sustainability: Green Concepts in Action

◆ Eco-Friendly Materials: Protecting the Environment

Recyclable and biodegradable materials are becoming increasingly popular in the wire harness industry, reducing environmental pollution and damage at the source. These materials ensure that wire harness products can coexist harmoniously with nature throughout their entire lifecycle—whether during production, usage, or disposal. They transform wire harnesses from environmental offenders to protectors, contributing positively to the planet's sustainable development, much like a trickle of water that combines to form a powerful force for ecological protection.◆ Energy Conservation and Emission Reduction: Promoting Green Manufacturing

The industry is actively adopting energy-efficient and environmentally friendly production processes, with upgrades to equipment and optimization of procedures at every stage of production. This is no longer a hollow slogan but is deeply integrated into every aspect of manufacturing. Companies are reducing energy consumption and pollutant emissions by using advanced energy-saving equipment and streamlining production processes, laying a solid foundation for sustainable development and creating a green path for industry growth. It is like painting a fresh, green canvas that harmonizes industrial development with environmental protection.◆ Circular Economy: Promoting Resource Rebirth

Building an effective wire harness recycling and reuse system has become a key measure for the industry to pursue sustainable development. Discarded wire harnesses are processed through meticulous classification, disassembly, and reprocessing—like undergoing a rebirth, they regain value. This process creates a virtuous cycle of “production - usage - recycling - reuse,” driving the industry toward a green circular economy. Not only does this reduce dependence on new resources and lower production costs, but it also contributes actively to environmental protection, injecting continuous energy into the industry’s sustainable development.

4. Future Outlook

Looking ahead, with continuous breakthroughs and widespread adoption of cutting-edge technologies such as 5G, the Internet of Things, and AI, the wire harness industry will have an even broader development horizon. Intelligent technology, lightweight materials, and sustainability will serve as powerful core drivers, guiding the industry toward higher efficiency, better environmental performance, and stronger levels of intelligence. On the global stage of industrial transformation, the wire harness industry will shine even brighter, becoming a crucial force driving the development of related fields, writing its own glorious chapter, and contributing unique value to human progress.Conclusion

The technological innovation storm in the wire harness industry is sweeping across the globe. This storm presents unprecedented opportunities, like opening a door to wealth and development for businesses, but also brings tough challenges, setting numerous obstacles along the way. To survive, companies must keenly capture the pulse of the times, like agile hunters tracking their prey, boldly embrace new technologies, and continuously refine their core competencies. Only then will they stand firm at the forefront of this wave, emerging victorious in the competitive market and becoming leaders of industry transformation, adding their own bold stroke to the industry’s development.

Message

If you are interested in our products, please fill in the message form below. Our sales representative will contact you within 24 hours.